JUNHE®2550 Monocrystalline cell texturing auxiliary additives

JUNHE®2550 Monocrystalline cell texturing auxiliary additives is a water-soluble, non-toxic and non-hazardous additive that meets the requirements of environmental protection. This product can form micron-level pyramid velvet on the surface of silicon wafers by improving the etching selection ratio of inorganic alkali on silicon, thus achieving good light trapping effect.

Product Details

Introduction

JUNHE®2550 Monocrystalline cell texturing auxiliary additives is a water-soluble, non-toxic and non-hazardous additive that meets the requirements of environmental protection. This product can form micron-level pyramid velvet on the surface of silicon wafers by improving the etching selection ratio of inorganic alkali on silicon, thus achieving good light trapping effect.

Low weight loss (reduced fragmentation), strong washability, and fleece consistency are achieved at lower process temperatures.

Technical Parameters

| Compositions | Contents | CAS No. | EC No. |

| Pure water | 95 – 97 % | 7732-18-5 | 231-791-2 |

| Sodium lactate | 2 – 2.5 % | 532-32-1 | 220-772-0 |

| Sodium epoxysuccinate | 1-1 . 5 % | 51274-37-4 | / |

| Surfactant | 0 . 01 – 0 . 05 % | / | / |

| Preservative acid | 0 . 1 % – 0 . 2 % | 137-40-6 | 205-290-4 |

Features

- Environmental friendly: no need to use IPA and other alcohol products, can achieve selective etching.

- Low production costs: low additive amount, velour production time is only 6-8 minutes, the cost is much lower than IPA velour production process.

- High etching efficiency: Compared with IPA velvet making process, the uniformity of velvet surface and reflectivity is better.

- No initial casting process: greatly reduce the cost of its own additives more environmentally friendly.

Application area

- The product is generally applicable to Perc, Topcon, HJT cell-production process

- It can be applied to all specifications of monocrystalline cells.

physical property

| sports event | Main parameters and technical indicators |

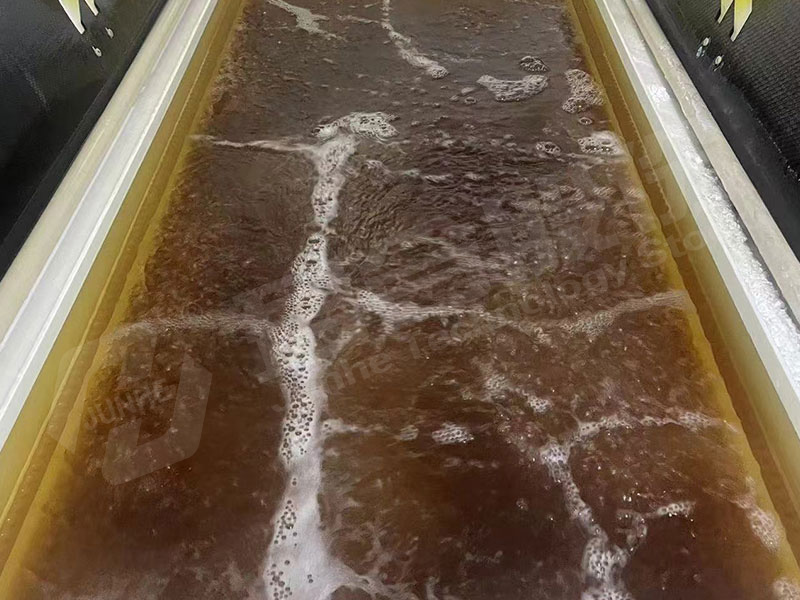

| Color, shape | Dark brown liquid |

| PH value | 13-14 |

| Densities | 1.1-1.9g/ml |

| Storage conditions | Store at room temperature away from light |

Instructions for use

- Add appropriate amount of alkali (1.5 – 2.5 % by volume of K O H (48 %)) into the tank.

- Add an appropriate amount of the product to the tank (0.5 – 0.8 % by volume).

- Warm up the fluffing tank liquid to 80°C+4.

- Put the silicon wafer into the fluffing tank, the reaction time is 400s-500s.

- Suggested weight reduction for a single wafer: 0.45 +- 0.06 g (210 wafers, other sources). 06 g (210 wafers, other wafers are converted proportionally)

Use Cases

Taking the example of Jagat Weitron’s trough-type velvet making machine using the no-first-cast process.

| process flume | Pure water | Norephedrine

(45%KOH) |

Additive(JUNHE®2550) | time | temp | weight loss | |

| velvet | First liquid dispensing | 437.5L | 6L | 2.5L | 420seconds | 82℃ | 0.47±0.03g |

| Liquid infusion | 9L | 500ML | 180ML |

Caveat

- The additives need to be kept strictly away from light.

- When there is no production in the production line, replenish the liquid and drain the liquid every 30 minutes, and it is recommended to drain and re-dispense the liquid if there is no production for more than 2 hours.

- The commissioning of the new line needs to be based on the production line of each process to do process matching, so as to maximize efficiency. Recommended processes can be referred to debugging.