JUNHE ® 2523 Diamond wire cutting fluid

JUNHE®2523 Diamond Wire Cutting Fluid is used in the cutting process of various super-hard and brittle materials (monocrystalline silicon, polycrystalline silicon, germanium, gallium arsenide, quartz, indium gallium nitride, gemstones, non-metallic materials, etc.), and it has excellent lubrication, cooling, anticorrosion, anti-corrosion, anti-rust, and hydrogen inhibition functions, and the surface of the wafer has low TTV and no wire traces after cutting and it is able to prolong the service life of the diamond wire.

Product Details

Introduction

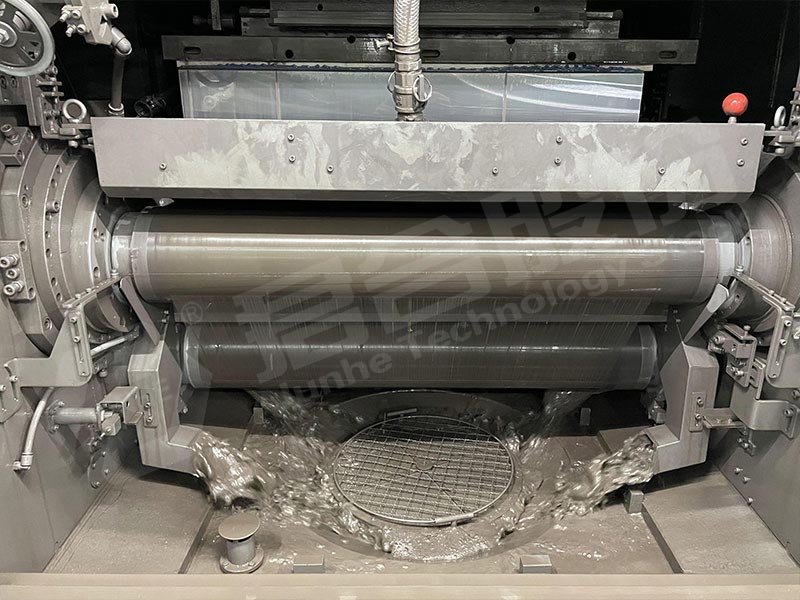

JUNHE®2523 Diamond Wire Cutting Fluid is used in the cutting process of various super-hard and brittle materials (monocrystalline silicon, polycrystalline silicon, germanium, gallium arsenide, quartz, indium gallium nitride, gemstones, non-metallic materials, etc.), and it has excellent lubrication, cooling, anticorrosion, anti-corrosion, anti-rust, and hydrogen inhibition functions, and the surface of the wafer has low TTV and no wire traces after cutting and it is able to prolong the service life of the diamond wire.

Maintains a low level of wire breakage, stable yield, and adapts to various processes.

Features

- Good cleaning ability:Containing unique chemical cleaning additives, it makes the cut silicon wafer clean and easy to clean after cutting.

- Excellent lubrication ability:Excellent lubrication can effectively prevent brittle chipping or scratches from occurring on the wafer during the cutting process, reduce the surface roughness and surface warpage of the wafer, and minimize the total thickness deviation of the processed wafer.

- Environmental friendly:Selection of environmentally friendly materials, less foam, low cost of waste water treatment, easy to use.

- Good dispersion performance:Unique suspension to avoid silicon powder deposition to block the machine pipeline.

- Strong adaptability:Good compatibility, suitable for offline or large cycle.

Technical Parameters

| Item | Appearance | Density (20℃kg/L) | pH 5% aqueous solution, | Rotational viscosity (25℃, mPa-s) | Surface tension (0.3% aqueous solution, mN/m) | Conductivity (1% aqueous solution, 25°C, us/cm) | COD

(mg/L) |

| Reference | Colourless transparent liquid | 1.00±0. 10 | 5.0~7.0 | <200mPa.s | 20~35 | >1us/cm | ≤15,0000 |

| Testing reference standard | Visual assessment | ASTM D4052 | GB/T 23769 | GB/T5561 | GB/T22237 | GB/T6616-2009 | HJ 828 |

If the customer’s demand is within the parameter range of our products, we can specify the corresponding products.

Application area

- Solar photovoltaic silicon wafers (monocrystalline, polycrystalline) diamond wire cutting application, for off-line and large cycle system, can achieve stable operation.

- Satisfy all kinds of semiconductor wafer diamond wire cutting.