Product Details

Solution introduction and capacity planning

- This solution creates a fully automated production line for alkaline electrolytic cells, with automatic switching of multiple varieties of pole frames by rail stacking and transportation, compatible with the production of A, B and C pole plates. Flexible production, annual production capacity of up to 200 sets; compact line body, high space utilization, short transportation distance, safety, high efficiency, energy saving.

- This solution includes providing 3D models of water electrolysis hydrogen production equipment automation production line equipment, 2D general assembly drawings, foundation drawings, and third-party docking solution design and implementation (vertical lathe, vertical milling machine, logistics AGV, etc.), related information hardware and software design and implementation, equipment manufacturing, packaging, transportation, pre-transportation warehousing, insurance, taxes, shipping, unloading, installation, commissioning, production support, technical information, spare parts, training, equipment manual, equipment maintenance manual, acceptance, quality assurance, after-sales service, etc.

- Capacity planning: It is expected to produce 200 sets of electrolytic cells per year, 325 electrolytic cells per set, 260 working days per year, 20 hours per day, equipment operation rate of 90%, and equipment failure rate ≤1%.

Product Information

- Product size compatibility: compatible with the production of alkaline electrolytic cells of three diameters: A, B, and C.

Specifications Pole frame (after processing) Outer diameter/mm Inner diameter/mm thickness/mm weight/kg A 2600 2400 12 95 B 2000 1800 11.2 65 C 1800 1600 11.2 50 - Automation requirements: The overall automation level of the workshop is relatively high, there must be enough material buffer areas in the workshop, and logistics should be automatic.

- Delivery period: Installation within 4 months after the project starts, installation and commissioning within 6 months, and the installation and commissioning time is expected to be about 2 months.

- Delivery location: Delivery and installation at the location designated by Party A.

- Warranty requirements: The equipment is installed and commissioned, and the period is within 24 months from the date of formal operation.

- Environmental characteristics: Working environment temperature 0-40 ºC.

- Humidity The average relative humidity is: 20-95%RH (no condensation, no frost)

Overview of key workstation equipment functions

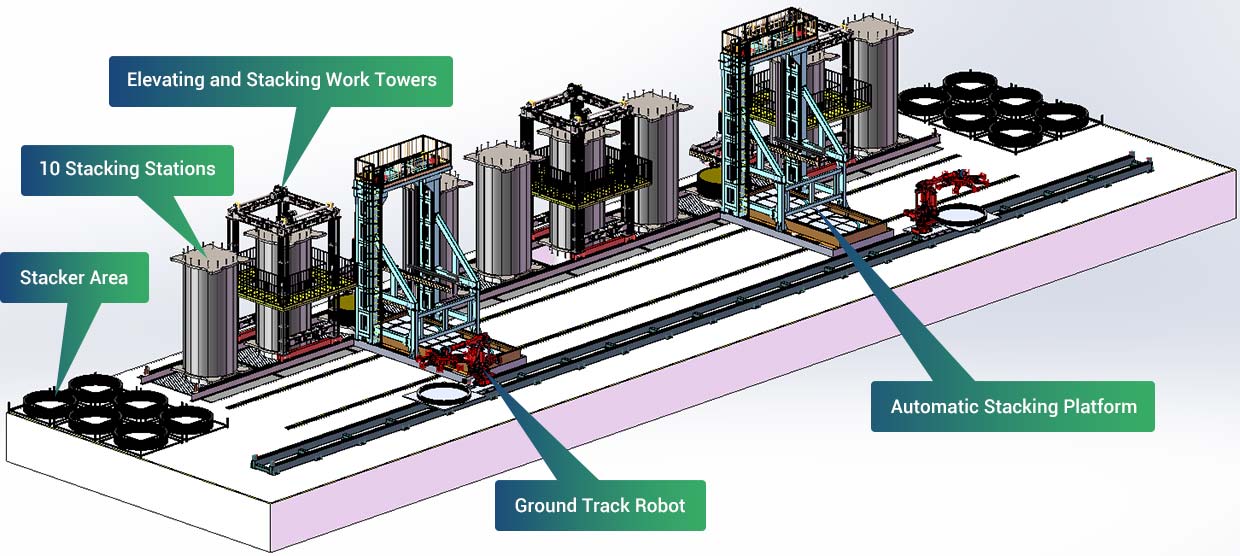

1.Automatic stacking process

- End plate positioning work positioning, lower end plate loading to stacking station

- Ground rail robot automatically loading, plate loading to exchange workbench

- Manual placement of sealing pads and diaphragms

- Alternate conveying of exchange workbench

- Automatic grabbing after positioning and distance measurement of the gripper

- The gripper moves the material to the stacking station

- Automatic material discharge after positioning and distance measurement of the gripper

- Repeatedly stack the corresponding number of plates

- Upper end plate loading to the stacking station

- The stacking work tower is translated into place

- The working tower operating platform rises

- The operator hoists the tensioning screw

- The tensioning screw is repeatedly locked

- Stacking is completed

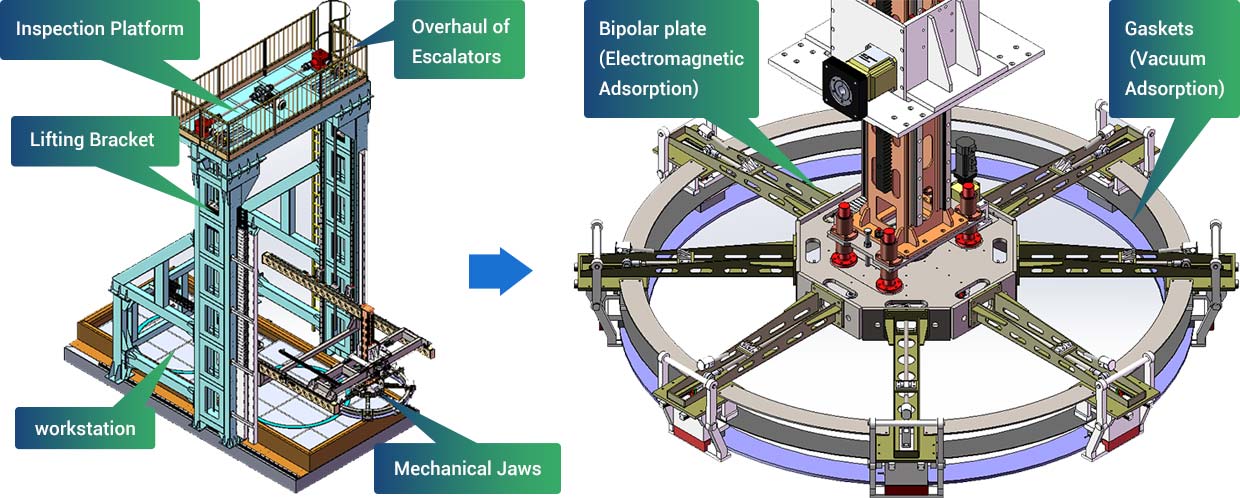

2.Assembly components of fully automatic stacking equipment for pole frames

- Stacking tower: 2 sets

- Ground rail robot: 2 sets

- Electrolytic cell stacking station: 10

- Automatic stacking workbench: 2 sets

- Control cabinet: 1 set

- Distribution cabinet: 3 sets

- End plate positioning tooling: 10 sets

3.Layout of the pole frame automatic stacking equipment assembly line

4.Introduction to the pole frame automatic stacking platform