JUNHE ® 1688 Single-layer and double-layer photovoltaic glass anti-reflection coating fluid

Product Details

Introduction

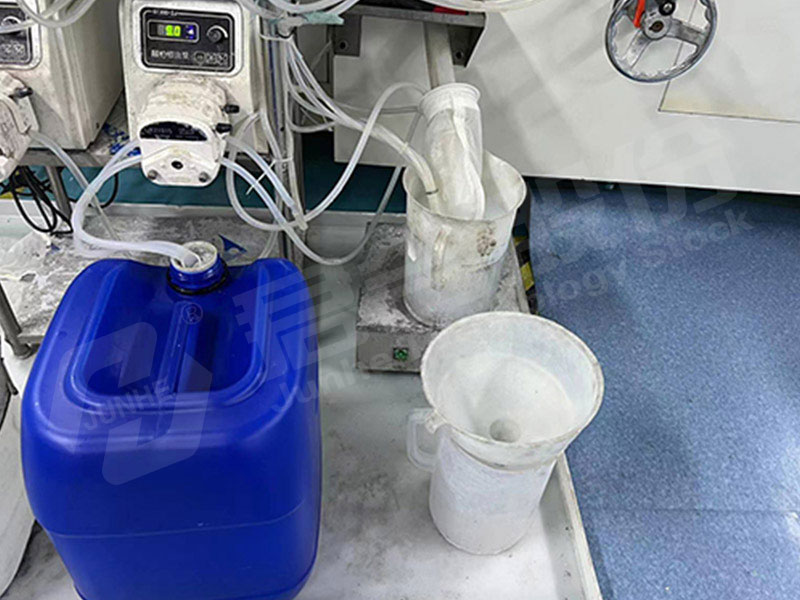

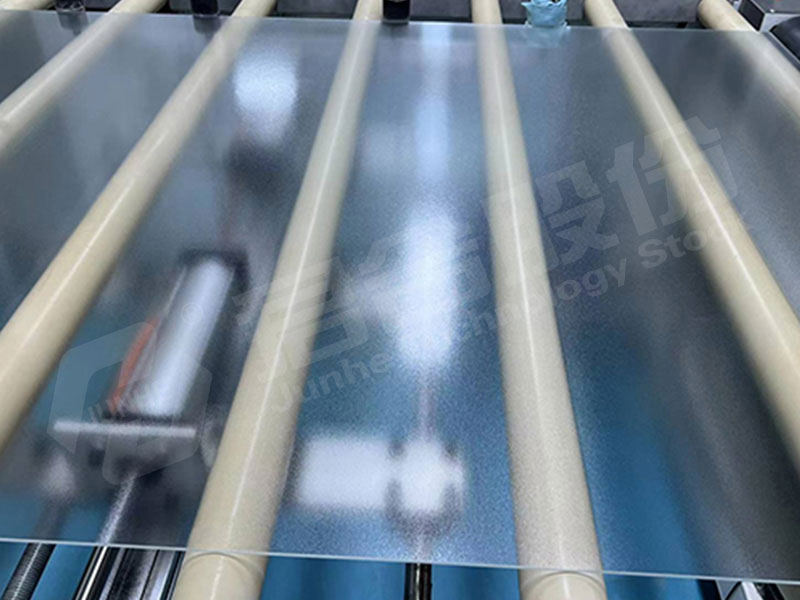

JUNHE®1688S single-layer coating solution and JUNHE®1688D double-layer coating solution are milky-white liquids obtained by reacting hollow silica nanoparticles with reactive groups with organic substances. The coating liquid is coated on the glass surface by roller coating process. After medium temperature curing and high temperature sintering, the organic matter is completely burned off, the nanoparticles will be tightly bonded with each other and rely on the hollow structure of the silica nanoparticles to produce a lower refractive index of the film layer.

By controlling the ratio of acid value and related solvents, we provide customized products in a variety of environments, achieving the perfect blend of easy application and long-term reliability in the welding field.

Technical Parameters

| Item | Standard Parameters | Test Conditions |

| Appearance | milky white | Visual Assessment |

| pH value | 4±1 | pH Indicator |

| Relative Density | 0.82±0.05 | specific gravity method |

| Solid content | 3.0±0.4 | 120℃,2 hours |

| viscosity | 2.0±0.5 | 25℃ |

Features

1、Good transmittance enhancement effect

Single-layer coating liquid mass production transmittance can be stabilised at 2.2-2.30%; while the actual transmittance enhancement effect of single-layer coating liquid mass production in the industry during the same period is generally 2.15-2.25%.

Double-layer coating liquid has a unique double refractive index matching, forming a highly efficient double-layer transmittance enhancement film, increasing the transmittance rate of about 2.45-2.55% (relative to the uncoated glass), while the actual transmittance increase effect of single-layer coating liquid in the industry is generally 2.15-2.25%.In the same period of time, the monitoring of the actual transmittance enhancement effect of double-layer coating liquid in bulk in the industry is generally 2.35-2.45%.

2、Good after-sales service

Our company is equipped with a number of engineers with more than 10 years of experience in coating, who can follow up and cooperate with customers on site according to their requirements to ensure continuous and stable production.

Application area

Mainly used on photovoltaic glass surfaces