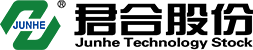

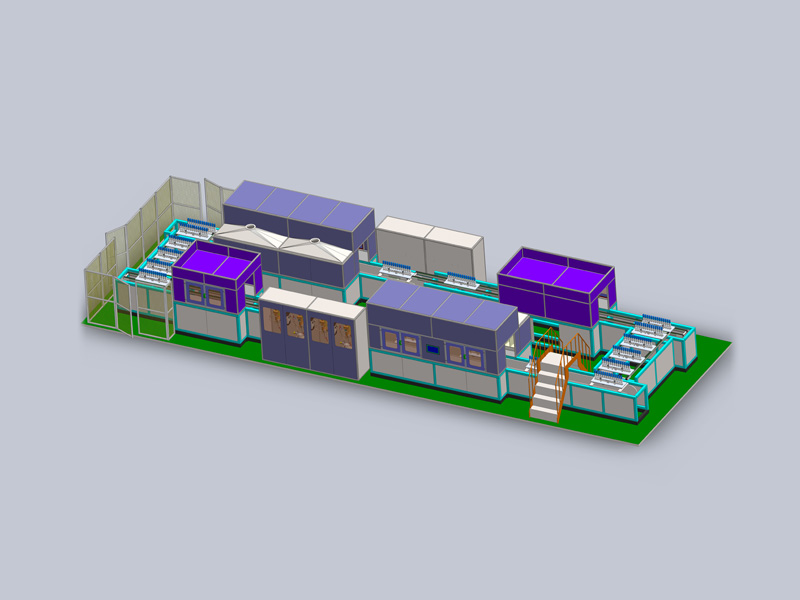

UV coating production line for battery shell

This production line solves the existing battery production using laminating film is easy to bubble, wrinkle, slow production beat, high rework rate and rework difficulties and other technical pain points. It has the advantages of better insulation performance, excellent bonding strength, good anti-corrosion and chemical resistance, high paint recovery rate, comprehensive utilization, environmental protection and low energy consumption.

Product Details

Introduction

This production line solves the existing battery production using laminating film is easy to bubble, wrinkle, slow production beat, high rework rate and rework difficulties and other technical pain points. It has the advantages of better insulation performance, excellent bonding strength, good anti-corrosion and chemical resistance, high paint recovery rate, comprehensive utilization, environmental protection and low energy consumption.

Technical Parameters

- Production speed: ≤2 seconds/piece

- Spraying film thickness: 110μm (±10μm)

- Product yield: ≥98

- Comprehensive utilization rate of coating: ≥75

Advantages

- Good insulation properties

- Excellent adhesion

- Fully automatic coating

- High efficiency and quality

- High coating recovery

- Compatible with different cell sizes

- 5-side or 6-side coating

- Fast curing

- Compact space

- Low energy consumption

- Good corrosion and chemical resistance

- Easy handling

- Fast fault detection